I’ve noticed a lot of people in the agile and lean communities lately talking about the Cost of Delay. I think it is a great idea (I wrote about the concept in an article in IEEE Software “Value Creation and Value Capture” and again in our book “Stand Back and Deliver.”). But as much as I like love the idea, I hate the name. Why? If there are two things that the software industry is obsessed with it is cost and delay. However, “cost of delay” is really not really about cost — it is about value loss. I’ve run across people that have diligently calculated the cost of delay as the actual costs that would be incurred by having the development team work longer. It is true that these costs are part of cost of delay, but that is totally missing the big aspect of cost of delay which is the value lost due to delay. That is why I would prefer to call it “Value Lost from Delay.” I recognize that adding a 4th word makes it much less desirable. Plus, cost is such a loaded word, partricularly in IT. I’m resigned to Cost of Delay being here to stay, but at least when you hear that phrase think “Value Lost from Delay.”

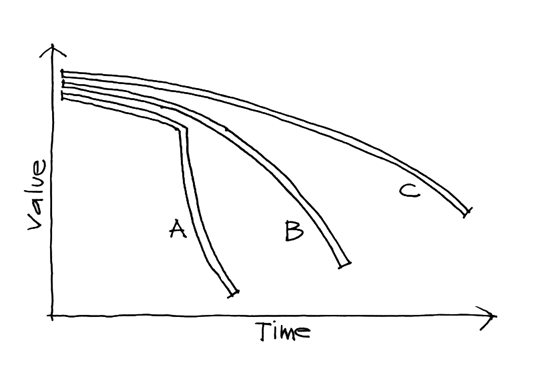

So given this first cognizant dissonance, how do we actually use the Cost of Delay? Typically, rather than calculating a number, I prefer looking at patterns of behavior. The following picture illustrates 3 different patterns showing value loss as a function of time. In curve C, the value does not drop off rapidly and the value loss from delay is a combination of the time value of money, the actual incremental costs, and the relatively small amount of market loss from the delay. This is contrasted with curve A where the value drops precipitously once the deadline passes. Examples of this include major events such as the Olympics or a conference. Other cases where value may drop off significantly, but perhaps not drop to zero include seasonal items such as games during the Christmas season.

So this chart gives us an indication of the value loss (or cost) due to the impact of missing the target delivery date. Our tendency is to treat everything as if it matches the “A” pattern. Invariably, when I have had mature conversations with stakeholders I find that only a few projects are really “A” and far more are actually “C”. That is one important realization. But what else is missing from this conversation? What about the creation of value in the first place? After all, what is more important: getting it right, or getting it done on time?

I once worked at an organization that was a market leader and had gotten to that position by extreme focus on strategy, customer, and quality. The only problem was that they had some challenges with meeting the aggressive schedules that they set. A new leader came in and was committed to changing that. He could have it all, including and most importantly having it on time. What did the organization do? Of course they shipped on time. But features and quality were not up to the usual high standards. What was the reaction from our customers? They coined the term “CRAP ON TIME!” Not the type of ringing endorsement that you want from your customers.

What’s missing from the Cost of Delay discussion is the COST OF CRAP! Using my own logic from above, I should be calling this the Value Lost from Crap. But I know better. Cost of Crap is much catchier. Not only is it shorter but it has alliteration!

What are some other examples of the Cost of Crap?

FORD Taurus

From Aaron Shensar from the Stevens Institute in “Strategic Project Leadership – Toward a strategic approach to project management”

The first generation of Ford Taurus turned out to be the best-selling car in America in the late 1980s. Conceived in the early 1980’s and introduced in 1985, it used a unique standard for project management and product development. It took full advantage of cross-functional teams and concurrent engineering practices; established close ties with vendors and subcontractors, and was characterized by a strategic spirit of focusing on customer needs and strong synergy with the business. The result was a remarkable business success, and customers simply loved the car. Yet, when the project was completed, the project manager was fired. The reason was that project completion was late by three months.

In contrast, the second generation of Ford Taurus was developed in the early 1990s and completed in 1996. With increased competition and the remarkable success of Japanese imports, Ford had hoped to reestablish Taurus, once again, as the best-selling car in America. But the new project manager learned the lesson of his predecessor: He considered project schedule as the most important criteria, and made sticking to schedule the ultimate goal, while sacrificing other issues. Vendor relationships, team spirit, and product integration were just few of the things that had suffered. The second generation of Taurus turned out to be a disappointing business experience. Although the project was completed on time, it did not recapture the position of the best-selling car in America and Ford was not able to repeat its outstanding success of the first Taurus (Walton, 1997).

WinWord 1.0

Winword 1.0 is often cited as an example of very poor software estimation and execution. The original plan in 1984 called for a delivery in 1 year. The project ended up taking 5 years before it commercially shipped. Certainly they had a ridiculously ambitious schedule. They had huge uncertainties as they were entering into a new market space for Windows based word processing with a technology base (Windows) that was constantly evolving under them. Those that were setting the aggressive target were probably doing so by calling out something akin to the Cost of Delay – “if we don’t get out to the market within 1 year we will lose our market opportunity.” Well, 5 years later they came out with a product in a market strongly dominated by an entrenched competitor (Word Perfect) with about 50% market share, and in a very short period of time became the dominant market leader. What would have happened if they had come out with an inferior product in order to avoid the cost of delay? Market acceptance would likely have been negligible. The cost of delay would be meaningless because there would have been little to no revenue to lose. Instead, by waiting until the product was sufficient to meet core customer needs they were able to generate substantial value. Stan Liebowitz of the University of Texas looked at the market share of Word vs. WordPerfect since 1986. Was Winword 1.0 a failed project because it was 4 years late? I would contend that the value gain from delay was enormous compared to what would have happened from shipping an inferior product. Perhaps the cost of delay was negative?

Rain Delay

My good friend and book partner Kent McDonald had this story to offer up.

I had some roof damage from a hail storm in May. We didn’t realize it until a roofing company (let’s call them Blackstone) came by trolling for business and told us we probably had damage. They said call our insurance and they would mark the roof when the adjustor came out.

Adjustor came out, and suggested a different roofing company (let’s call them Petticord) which is part of their Preferred Vendor Network. Even though Blackstone pointed out that we had damage, and also said they would do the job for less than their own estimate or the insurance estimate (this raised red flags) we went with Petticord because the insurance company (let’s call them Allied Insurance) would work directly with Petticord, and it would be fairly low effort for us. When I told Petticord that we were going with them, I asked when they may get to it. I asked merely for information. They said the next week.

On Friday, I got home from Des Moines and there were packages of shingles on my roof. Petticord called and said they were going to try and get it done over the weekend or Monday. I commented that would be good, but I wasn’t in an all fired hurry and asked if they were sure they wanted to be doing roofing in the rain. All weekend and Monday there were several storms forecast.

On Monday (forecast 80% chance of severe thunderstorms) a roofing crew shows up at our house and starts pulling shingles off and putting shingles on. About 1:30 in the afternoon, a wicked storm blows through blowing the shingles the roofers had just put down and causing several leaks in our house. Upon talking to people at Petticord and after listening to all their excuses, they basically took a risk that bad weather wouldn’t hit us (we were looking at the radar all day, we have advanced technology) because they felt schedule pressures. Not from me mind you.�

Now they are having to spend even more time at my house to fix more than just the roof because they took an unnecessary risk to try and stay on an unrealistic schedule.

There are many, many other examples of the “Cost of Crap:” Healthcare.gov, Windows Vista, Windows 8.0 are certainly a few cases where consumer reaction was not positive. So, while there is value to understanding the “Cost of Delay”, there is even more value to understanding the “Cost of Crap.”

“Value Lost from Delay” does have a cognitive bump that had me reading the term backwards. Try “delay” as a verb, not a noun?

I can offer “Delayed Value Lost” or “Delayed Value Shrinkage.”